Description and areas of use of the product:

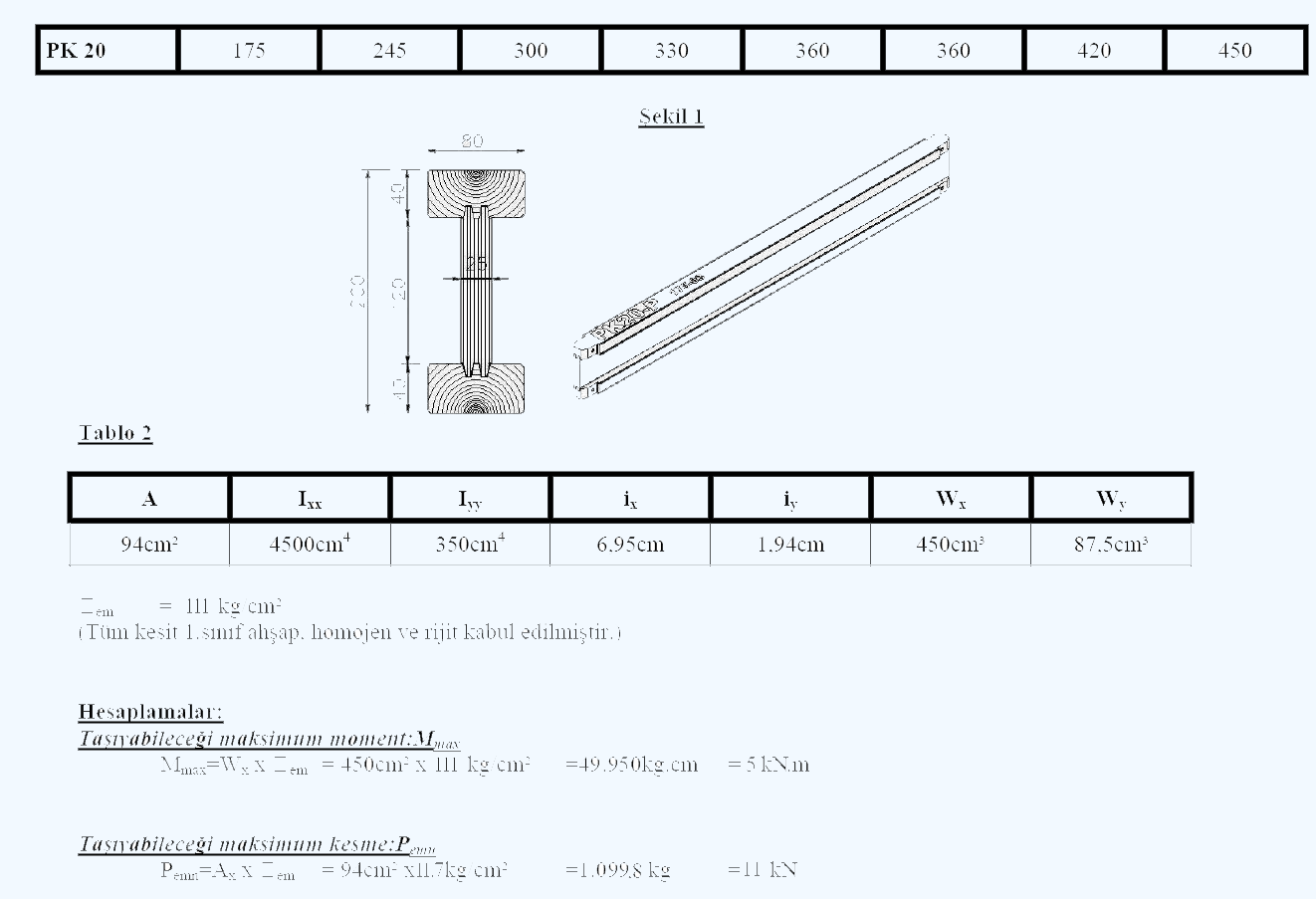

It is manufactured from a component, of which lower and upper heading is40x80mm solid wood and intermediate body is 25mm thick plywoodand,in accordance with the following physical dimensions (Figure 1). Components are fixed to each other with threaded joins and special press by using cool-applied glue thus sliced wooden girders are created. Since a greater moment of inertia is obtained by using less wooden material due to its l form, it is used as an economical concrete formwork beam and purlin. Curtain is an ideal beam and purlin for the rest and flooring formworks. In addition to that it is used as roof purlin and beam, it is a composite material that is economicaland with a large carrying capacity wherever wood is used as supporting beam. Section values of the beam are given in Table-2. It can be manufactured in various heights upto 450 cm. As well as it can be manufactured at any height on request, it is standardized as in Table-1.

Functional features of the product:

Its shape! Since its moment of inertia is about 3 times higher than a wooden grid with the same amount and weight, it provides the ideal efficiency as a construction material that is light and with a high carrying capacity. It makes saving to reduce significantly concerete flooring formwork strength. Since the form is manufactured from wood, it shall not become deformed under sun and rain; thus flooring and curtains with smooth surfaces that don’t require plaster are obtained.

|

Wood

|

:

|

Lower and upper headings are kin-dried

spruce or fir lumber, and body is

water-resistant body plywood.

|

|

AdhesiveGlue 1

|

:

|

PVA Ac D3 Norm Glue

|

|

Paint and Protection

|

:

|

Water Based External Paint,

impregnation.

|

Table 1 (Standard Sizes)