- Thanks to its lock and load transfer features at cup-lock scaffolding connection points, it is an ideal system for formwork board scaffolding. - High load-carrying capacity,quick installation and dismantling and that it can be used for any project are important reaons to prefer this system.

CUP TYPE (CUPLOCK) SCAFFOLDING SYSTEM

• It is manufactured from ST37 steel pipes subjected to mechanical testing and including the standard TSE certificate.

• Since all materials are automatically manufactured in the same standards, any problem doesn’t occur at the stage of installation for the application. Thus, installation can be realized in a shorter time and labor can be saved.

• Vertical element carrying capacity can be increased up to 6 tons.

• Cuplock Scaffolding System has been used safely even at the height of 100 meters.

• Vertical element’s moment of inertia is 11.60cm4;

Momentum of strength is 4.80 cm3; Buckling radius is 1.60 cm;

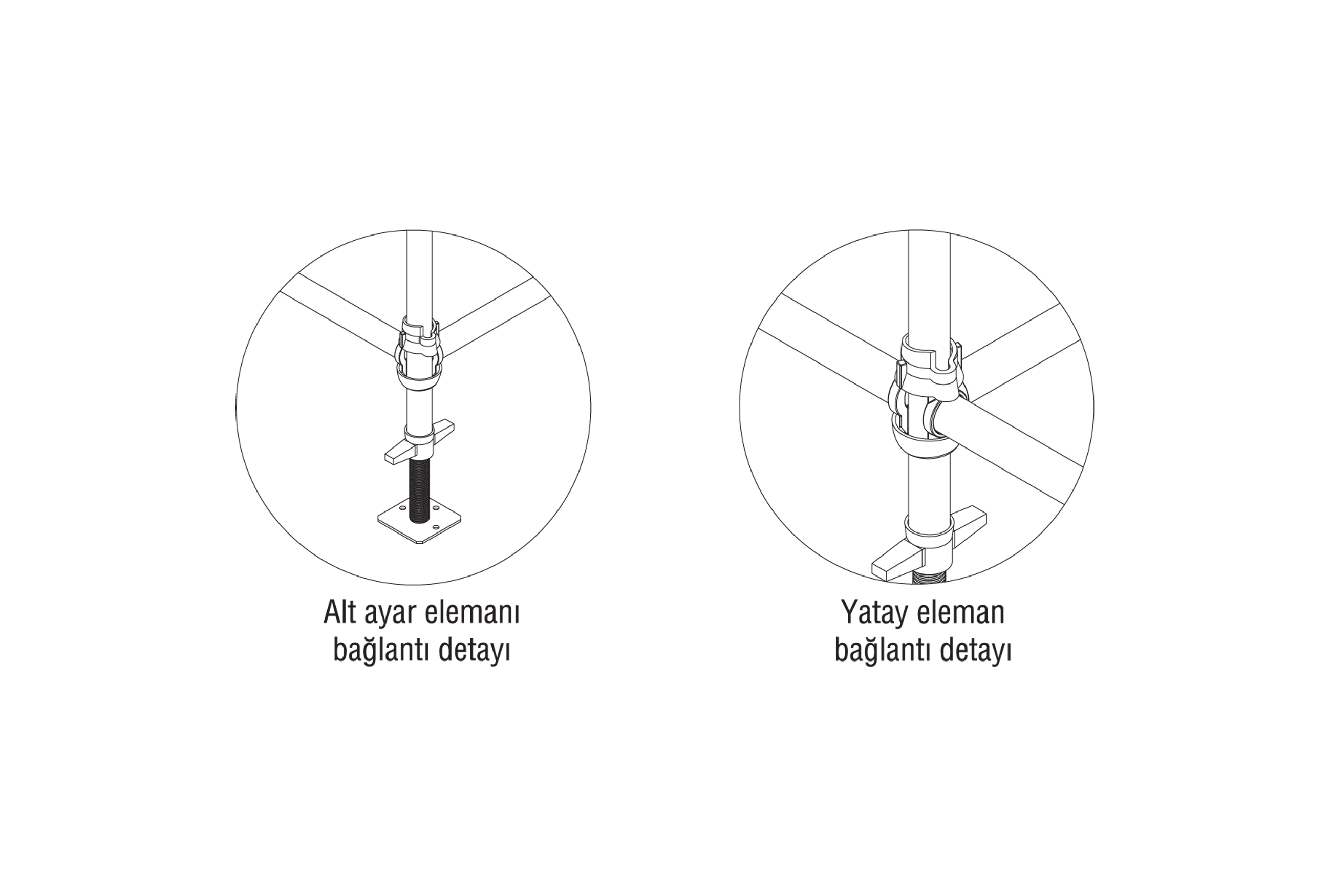

• Vertical Element is manufactured from 048x3mm pipes; and Horizontal Element is manufactured from 0 48 x 2.5 mm pipes.

• Circular welding is done with automated robots.

• Weldings are are full weldings, not point.

• Welding thickness is 25%thicker than the standard weldings. 1 mm welding wire is used.

• Supervisor service is provided.

• The same materials shall be adapted by our project department according to your other projects.